September 9, 2013 – Super Systems Inc. (SSi) has delivered a complete furnace control panel for a continuous austemper line at American Heat Treating Inc. of Monroe, Connecticut. The continuous shaker austemper line has delivered millions of parts for many industries. American Heat Treating sought to implement more automation and traceability, presenting an ideal opportunity to utilize SSi’s controls and engineering capabilities.

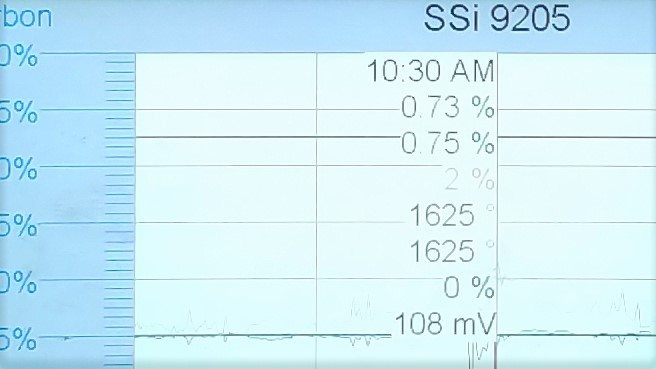

The goal of the project is to provide updated control equipment with a centralized control panel, traceability to process parameters, automated atmosphere control with redundancy, reduced floor space, and an easy to use operator interface. The furnace control panel will use the SSi Compact HMI interface to the PLC and 9205 process controller. Compact HMI will provide control to all I/O points, including I/O for temperatures, atmosphere, automatic feeder and belt speeds. An extensive alarming system will provide fast notification of critical conditions with suggested resolutions. SSi controllers have localized data acquisition for redundant data logging and a built in maintenance database. The maintenance database, a standard offering with the 9205 controller, provides conditional parameters so that maintenance can be tracked by the system, helping to reduce unplanned downtime. American Heat Treating already uses the SSi SuperDATA system to monitor several pieces of plant equipment. The new upgrades from SSi will tie into the SuperDATA system with existing process points from the austemper line, providing plant-wide visibility.

“American Heat Treating Inc. serves a variety of industries such as automotive, off road equipment, armament/weapons systems, consumer products, construction, firearms, medical, tool and die,” General Manager Larry Roether explains. “We have learned from our experience that SSi controls provide us with all the necessary tools to meet industry standards such as CQI-9 and provide tight process control. They have the resources to get it done efficiently and support us with our long term plans.”

Super Systems Inc., based in Cincinnati, Ohio, has been developing and manufacturing products for the thermal processing industry since 1995. SSi’s products include probes, analyzers, controllers, software solutions and engineered systems. With more than 100 years of combined experience, SSi has been addressing industry demands with technology customers need to be more efficient and produce higher quality products.

More information on SSi products and services can be found at http://www.supersystems.com.